Ukucocwa kweefa kuhambelana nohlobo kunye nobukhulu bezinto ezifakwe isitampu.Izikhewu ezingekho ngqiqweni zinokubangela ezi ngxaki zilandelayo:

(1) Ukuba umsantsa mkhulu kakhulu, i-burr ye-stamping workpiece inkulu kakhulu kwaye umgangatho wesitampu usezantsi.Ukuba i-gap incinci, nangona umgangatho wokubetha ungcono, kodwa ukunxiba kwe-faye kubi kakhulu, kunciphisa kakhulu ubomi benkonzo yokufa, kwaye kulula ukubangela ukuphulwa kwe-punch.

2Ukucocwa okuncinci kakhulu kulula ukwenza ivacuum phakathi komzantsi wepunch kunye neshiti lesinyithi kunye nenkunkuma ephindaphindayo.

(3) ukukhutshwa okufanelekileyo kunokwandisa ubomi bomngundo, ukukhupha umphumo kulungile, ukunciphisa i-burr kunye ne-flanging, ipleyiti igcinwe icocekile, i-aperture ihambelanayo ayiyi kukrwela ipleyiti, ukunciphisa inani lokusila, gcina ipleyiti ngokuthe tye, i-punching positioning echanekileyo. .

CNC punch die, isixhobo CNC punch, CNC fa

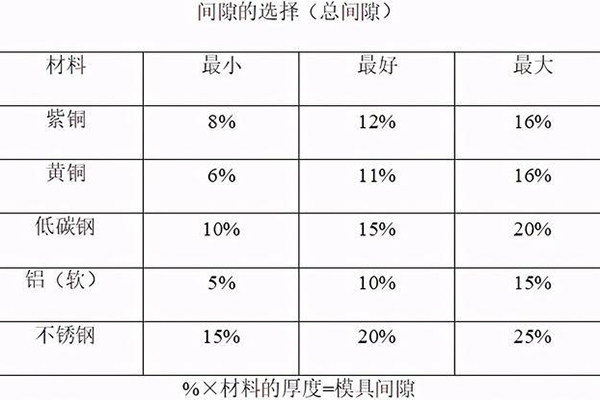

Nceda ubhekisele kwitshathi ukukhetha ukususwa kokungunda (idatha ekwitheyibhile yipesenti)

(1) Ukuba umsantsa mkhulu kakhulu, i-burr ye-stamping workpiece inkulu kakhulu kwaye umgangatho wesitampu usezantsi.Ukuba i-gap incinci, nangona umgangatho wokubetha ungcono, kodwa ukunxiba kwe-faye kubi kakhulu, kunciphisa kakhulu ubomi benkonzo yokufa, kwaye kulula ukubangela ukuphulwa kwe-punch.

2Ukucocwa okuncinci kakhulu kulula ukwenza ivacuum phakathi komzantsi wepunch kunye neshiti lesinyithi kunye nenkunkuma ephindaphindayo.

(3) ukukhutshwa okufanelekileyo kunokwandisa ubomi bomngundo, ukukhupha umphumo kulungile, ukunciphisa i-burr kunye ne-flanging, ipleyiti igcinwe icocekile, i-aperture ihambelanayo ayiyi kukrwela ipleyiti, ukunciphisa inani lokusila, gcina ipleyiti ngokuthe tye, i-punching positioning echanekileyo. .

CNC punch die, isixhobo CNC punch, CNC fa

Nceda ubhekisele kwitshathi ukukhetha ukususwa kokungunda (idatha ekwitheyibhile yipesenti)

Ulwazi lweshishini:

1. Indlela yokugweba impazamo yokuchaneka kwe-NC lathe

Umzi-mveliso we-lathe we-CNC ozenzekelayo ngoku ujongene nengxaki enkulu, i-high-end CNC machine tool yokungenisa ilawula.Ukususela kwidatha echaphazelekayo yokungeniswa kwesixhobo somatshini we-CNC, ukususela ngoNovemba ka-2012, i-China ye-CNC yesixhobo somatshini wokungenisa elizweni ngokubanzi ibonisa ukuhla, kodwa ixabiso lokungenisa liye lanyuka, elinokubonisa ukuba ukuthengiswa kwesixhobo somatshini we-CNC ephezulu kuyaqhubeka nokunyuka.Ungatsho ukuba umatshini ngokwawo, isixhobo somatshini we-CNC yimveliso ephambili yomatshini wokuzenzekelayo kunye nobukrelekrele, inqanaba lenkqubo yalo ye-CNC luphawu olubalulekileyo lokumisela inqanaba le-lathe ye-CNC ngokuzenzekelayo.Nangona kunjalo, i-90% yeenkqubo ze-CNC zasekhaya kufuneka zingeniswe kumazwe angaphandle.

2. Isebenza njani i-lathe ye-CNC

I-CNC lathe ingaqwalaselwa ngeentlobo ezimbini zetafile yemela: (1) itafile yodidi lwemela ngumvelisi weCNC uphuhliso kunye noyilo, ukusetyenziswa kwekholethi luhlobo.Inzuzo yolu hlobo lwetafile yemela yindleko ephantsi yokuvelisa kunye nokuveliswa, kodwa ukungabikho kokusebenza (2) itafile yemela yomhlaba wonke esekelwe kwinkcazo yendalo yonke (njengeVDI, i-French Institute of Technical Engineers) kunye nokuveliswa kwetafile yemela. , Abavelisi be-lathe ye-CNC banokukhetha kwaye baxhobise ngokwendima ye-CNC lathe amalungiselelo.1. Umthamo wokuvelisa we-CNC lathe unokwandiswa kakhulu emva kokuba itafile ejikelezayo yokusika ifakwe kwitafile yokujikeleza.Ngokomzekelo, ukusetyenziswa kwetafile yokusika i-rotary ukwenza i-radial drilling kunye nokusika i-axial groove.2. CNC lathe CNC blade in CNC lathe okanye imveliso milling iziko machining iindawo zokusila, kufuneka zisekelwe CNC lathe isakhiwo kwaye ingafakelwa inani lilonke CNC blade, olusebenzayo kunye nophando lwenzululwazi ukwaba blade NC phezu izixhobo itheyibhile iindawo. , kwaye ubeke ingqalelo ukuthintela i-CNC blade kwi-static kunye nomsebenzi, Ukuphazamiseka phakathi kwe-NC blade kunye ne-NC lathe, i-NC blade kunye ne-workpiece kunye ne-NC yayo.

Umsebenzi unokwahlulwa ngokwezi nkqubo zilandelayo: 1. Yenza iindlela zokubala zamanani kunye nobuchule bokucubungula ngokwemveliso kunye nokucubungula umxholo wobugcisa ochazwe kwinxalenye yemizobo.Ukusasazwa kunye noyilo lokuhamba kwenkqubo.2. Inkqubo yesixhobo sokulawula umatshini wokulawula amanani ngokweemfuno zolawulo lwamanani lwefomathi yefayile yokuqukuqela, kunye nerekhodi eneenkcukacha ngendlela yokubhalwa kwekhowudi kwisixhobo sogcino esiphathwayo, ngokutsho kwegalelo (imveliso ye-manual, i-electronic computer transmission, njl. .) indlela, umxholo wenkqubo yokuvelisa kunye nokuhamba kwenkqubo ukuya kumatshini wokulawula amanani izixhobo.3. Ukuhamba kweprogram yesixhobo somatshini we-NC (ikhowudi ye-NC) eyamkelwa yisixhobo somatshini we-NC, ikhowudi ye-NC iguqulwa ibe okanye yenziwe ngesandla ngumdwelisi weprogram kwi-software ye-CAM, ingcaciso yedatha yombhalo, ukubonakaliswa kubonwa ngakumbi, kulula iqondwe ngoko nangoko ngumdwelisi wenkqubo, kodwa ayinakusetyenziswa ngoko nangoko kuqwalaselo lwehardware.Isixhobo somatshini we-NC isixhobo se-NC esinekhowudi "inguqulelo yesiTshayina" yezixhobo zokubhala, izixhobo zokukhowuda zenziwe nge-0 s kunye ne-1 s yeefayile zokubini, emva koko uguqule ukukhohlisa i-X kunye no-Z ulwalathiso lwedatha yedatha yokufaneleka kwe-pulse yangoku, kunye nezinye iimpawu zedatha ezincedisayo, kunye izisombululo ngokohlobo uphawu umahluko kwizibuko imveliso NC isixhobo isixhobo somatshini, inkqubo yolawulo servo ukwenza lo mkhuba.

3. Ngexesha lemvula, kufuneka zigcinwe njani iileyile ze-CNC ezizenzekelayo

Ngexesha lemvula, ukugcinwa kunye nokugcinwa kwezixhobo zoomatshini kubaluleke kakhulu, kuba kwimozulu enjalo, izixhobo ziyakwazi ukungaphumeleli, kwaye iindawo ezininzi ezisezantsi kweChina zinemvula enkulu, kwaye ezinye iindawo zinezikhukhula.Apha, sazisa indlela yokugcina i-lathe ye-CNC ezenzekelayo kwixesha lemvula?

I-lathe ye-CNC ezenzekelayo sisixhobo sokuvelisa esichanekileyo, sineemfuno ezintathu eziphambili zokusingqongileyo:

(1) beka indawo ye-lathe ye-CNC ezenzekelayo kumgaqo womthombo wokungcangcazela, kwaye ayikwazi ukuba nelanga elithe ngqo, umoya nawo uyafuneka ukuze wome;

(2) Iimfuno zobonelelo lombane, amandla ombane kufuneka azinzile;

(3) Iimfuno zobushushu kunye nokufuma, iqondo lobushushu akufunekanga libe ngaphantsi kwe-30℃, ukufuma kungabi ngaphantsi kwama-80%.Kutheni sifuna iimeko ezinjalo?Vumela i-xiaobian ukuba icacise ukudideka kuwe: ukungcangcazela kokuqala kuya kuchaphazela ngokuthe ngqo umgangatho we-workpiece, ixesha elide lokuvezwa kokukhanya kwelanga kulawulo oluchanekileyo lwe-CNC lathe oluzenzekelayo nalo luyachaphazeleka;Okwesibini, ukuzinza kwamandla ombane yenye yezinto ezibalulekileyo zokuqinisekisa umsebenzi oqhelekileyo we-lathe ye-CNC ezenzekelayo, kuba amacandelo e-lathe ye-CNC ezenzekelayo nawo ayindawo echanekileyo, ukungazinzi kwamandla ombane kulula ukubangela umonakalo kwiindawo ezichanekileyo, okukhokelela kwi-lathe ye-CNC ezenzekelayo ayikwazi ukusebenza ngokufanelekileyo;Emva koko, iqondo lobushushu kunye nokufuma yinto ebalulekileyo yokuqinisekisa ukusebenza okuqhelekileyo kwamacandelo e-lathe ye-CNC, ubushushu obuphezulu kakhulu kunye nokufuma kuya kukhokelela kubomi obuncitshisiweyo bamacandelo enkqubo, ukusilela okwandisiweyo, kunye nokwenza ibhondi yothuli kwibhodi yesekethe, isekethe emfutshane.

Ukuthobela ngokungqongqo ikhowudi yombane

1. I-lathe ye-CNC ezenzekelayo kufuneka ifuneke ngokungqongqo ukufikelela kumhlaba, kunye nokusetyenziswa kweplagi yamandla amathathu, ukunciphisa ukuphazamiseka kwe-electrostatic, ukuphucula ukuzinza komatshini kunye nokukhuselwa komsebenzisi.Ehlotyeni, ngenxa yokusetyenziswa kwamandla ngokugqithisileyo kunye nexesha lemvula, kuya kuhlala kukho ukungazinzi kombane wombane, njl. njl., okukhokelela ekusileleni, kwaye nokutshisa umqhubi kunye nezinye izinto.Kunconywa ukuthenga i-voltage regulator yemodeli ehambelanayo.

2. Ukuphucula ukusetyenziswa kwe-CNC ngokuzenzekelayo kwe-lathe ye-CNC, i-CNC yokulawula amanani e-lathe ukuba izinga lokugijima aliphezulu, ukongeza kwimali, umphumo wawungaphantsi kokuveliswa kwakhona, kodwa uxhalabele malunga nento ixesha lewaranti, ngenxa yokuba i-CNC i-automatic CNC. Isixhobo se-lathe sinexesha lewaranti, umsebenzisi kufuneka asebenzise umatshini ngeli xesha, inxalenye encinci ibonakaliswe ngokukhawuleza, ukuba ilahlwe phantsi kwewaranti.Ukuba ayisetyenziswanga ixesha elide, ukuwohloka okanye ukonakaliswa kwezixhobo ze-elektroniki kunokukhawuleziswa ngenxa yokufuma kunye nezinye izizathu.Ngokukodwa kwixesha lemvula, kwakhona ufuna ukuqhuba umatshini ngokufanelekileyo.

3. Ileyile yeCNC ezenzekelayo yeCNC kufuneka isetyenziswe kwindawo elungileyo kuba umoya ufumile ngexesha lemvula.Kulula ukufuma kumoya ofumileyo kwaye ungaphumeleli.Kwaye ubeke ingqalelo kwiinkcukacha emsebenzini, ngoko qaphela ukuba ungazisi iimbrela kwindawo yokuvelisa, utshintshe izicathulo, njl.

4. Ngawaphi amacandelo aphambili omatshini we-lathe we-CNC oluzenzekelayo

I-1, i-automatic CNC lathe spindle bearing box: i-machining center spindle ibhokisi yebhokisi egxininiswe kwindawo ephezulu ekhohlo yebhedi.Isasaza intshukumo ejikelezayo yokufaneleka kwemoto ukuya kwibheringi yokusonta, kwaye ityhala icwecwe lokusebenza ukuze lijikelezise kunye ngokuhambelana nesixhobo.Ngokutshintsha indawo ye-rocker kwibhokisi, i-spindle bearing inokufumana iintlobo ngeentlobo zeereyishini zesantya se-positive kunye ne-reverse.

I-2, Ibhokisi yesixhobo: ibhokisi yesixhobo seziko lomatshini ligxininiswe kwicala lasekhohlo nasezantsi kwebhedi.Ngokutsho kwevili elijingayo, intshukumo ejikelezayo yokufaneleka kwentsimbi yokuphotha idluliselwa kwi-screw yebhola okanye isikrufu sokukhanya.Ukutshintsha indawo ye-rocker kwibhokisi, unokutshintsha umlinganiselo wesantya sebhola okanye isikrufu sokukhanya, kwaye emva koko ufezekise injongo yokutshintsha i-pitch yezinyo okanye isantya sokusika.

3, Ibhokisi yebhodi yesilayidi: Ibhokisi yebhodi yesilayidi emiswe ngaphandle kwesali yebhedi, kunye nesali yebhedi kunye kumzimba wesilayidi wesiporo sikaloliwe ukwenzela intshukumo ephindaphindiweyo ethe nkqo.Ngokutsho kwayo, isijivu sebhola okanye ukufaneleka kwebha yokujikeleza kwisali yebhedi, ukufaneleka kwemela ejijekileyo kabini.Inxalenye yerocker kwibhokisi yokuguqula inokusebenzisa intshukumo yesixhobo se-lathe esithe nkqo okanye esithe tye (intshukumo yokufaneleka, ukuqala okanye ukumisa).

4. I-rack yecala: I-rack yecala ifakwe kwicala lasekhohlo lebhedi.Ixhotyiswe ngegiya yokuhambisa etshintshanayo (ivili elijingayo), elithumela intshukumo ye-rotary fitness ye-spindle bear kwibhokisi yesixhobo.Lungisa igiya yothumelo kwirekhi yevili elijingayo kwaye usebenzisane nebhokisi yokusika kwimisonto yokusila enepitch eyahlukileyo.

I-5, Itheyibhile yeKnife: itheyibhile yomese egxininisekile kwi-drag draw encinci, esetyenziselwa izixhobo kunye nesixhobo se-lathe.

I-6, i-pallet ye-lathe echanekileyo ye-CNC: i-pallet ibandakanya i-saddle yebhedi, i-warping plate ephindwe kabini, ivili kunye ne-double warping plate encinci yamacandelo amane.Isali yebhedi ixhonywe kwiintsimbi zesilayidi ngaphandle komzimba webhedi kwaye inokushukunyiswa ngokuthe nkqo ecaleni kweereyili zesilayidi zomzimba webhedi.Ipleyiti yokulwa kabini inokuhamba ngokuthe tye ecaleni komzila wesilayidi we-dovetail ekupheleni kwesali yebhedi;Ipleyiti encinci ejikajikayo inokuhamba ngokuthe nkqo ecaleni kwesilayidi se-dovetail phezulu kwevili.Emva kokuba ivili lijikeleza kwi-engile enye yokujonga, ipleyiti encinci ye-warping inokutyhala imela ukuba ihambe ngedayagonali, esetyenziselwa ukungqusha imiphezulu emifutshane yangaphakathi nangaphandle.

I-7, i-Lathe tool rest: isihlalo somsila sifakwe kwisilayidi sesilayidi somzimba webhedi, kwaye sinokushukunyiswa ngokuthe nkqo ecaleni kwesilayidi somzimba webhedi.Umngxuma we-cone wenkcazo ye-sleeve kwisibambi sesixhobo se-lathe unokufakwa, i-twist drill, i-reamer, itephu kunye nezinye iimela kunye nezixhobo, ezisetyenziselwa ukuxhasa i-workpiece yemveliso, ukubhola, ukudika, ukucofa njalo njalo.

I-8, umzimba webhedi: umzimba webhedi sisiseko senkxaso ye-lathe ye-CNC.Igxininiswe emilenzeni yokulala ekhohlo nasekunene, isetyenziselwa ukuxhasa amacandelo aphambili ecala le-lathe, kwaye ibenze bagcine ubunzima obunxulumene nomsebenzi.Amaqela amabini eentsimbi zesilayidi kumzimba webhedi abonelela ngesikhokelo sokuhamba ngokuthe nkqo kwebhedi yesali kunye nesixhobo sokuphumla.

9, Ball screw: ibhola screw isitshixo sokugaya intambo, yenye yezona ndawo zibalulekileyo zomphetho we-lathe.Ukuze uhlale ugcina ukuchaneka kwebhola ye-screw, akuyimfuneko ngokubanzi ukusebenzisa isikrufu sebhola kwiziko le-automatic cutting.ng?

Ixesha lokuposa: Aug-12-2022